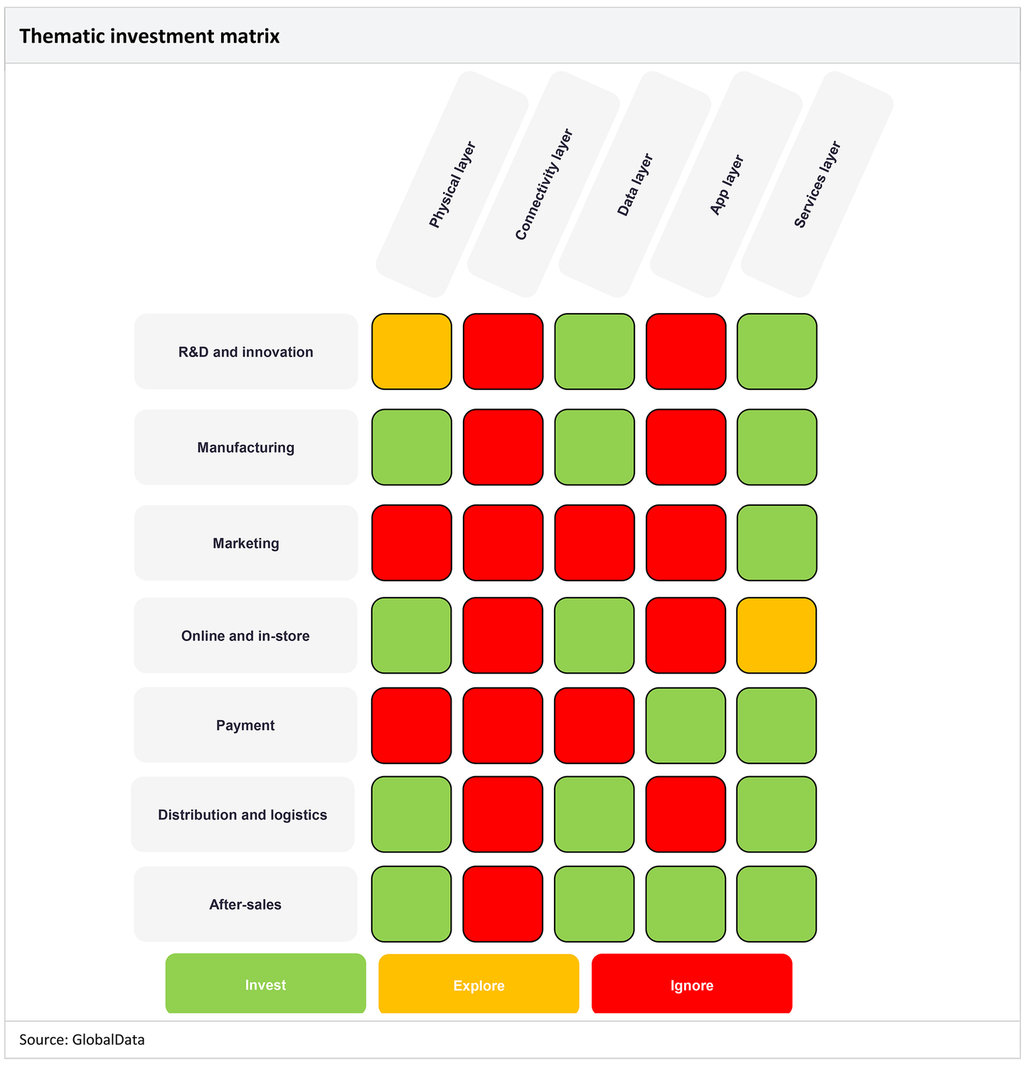

The matrix below details the areas of IoT in which consumer goods, foodservice, and packaging companies should focus their time and resources. GlobalData suggests that companies invest in technologies shaded in green, explore the prospect of investing in technologies shaded in yellow, and ignore areas shaded in red.

Physical layer

Companies in the manufacturing, online and in-store, distribution and logistics, and after-sales segments of the value chain should invest in the physical layer of IoT. For manufacturers and distributors, it can enable the tracking of goods and pallets. Radio frequency identification (RFID) and near-field communication tags can be used on physical items, facilitating after-sales support as these tags often redirect consumers to more information about the product and help them access customer support. RFID tags are particularly common among luxury goods brands, including Kering and LVMH, to prove authenticity and provide users with more information about the product.

Connectivity layer

Connectivity is not a layer in which companies from the consumer industries need to invest. They can outsource to a tech specialist, such as Amazon Web Services, rather than managing infrastructure requirements in-house.

Data layer

As IoT grows and develops, its sensors will generate even more data. Therefore, it is vital that all connected layers have networks with the necessary elasticity to manage big data so information can be effectively integrated, processed, and stored.

App layer

The app layer should be explored by the payments and after-sales segments of the consumer value chain, as this enables seamless transactions and in-app support after sales.

Services layer

Services have become a necessary addition to the IoT value chain over the last decade, as many IoT adopters lack the design, technical, integration, or data analysis skills to deliver a successful IoT implementation.

How IoT can help address the challenge of supply chain management

Installing IoT technologies across the value chain helps companies generate end-to-end overviews of their processes with live information on the activity at each stage. These technologies include sensors, cameras, GPS trackers, barcodes, smart labels, RFID tags, beacons, and more. They are cheap, and their deployment can bring significant rewards.

From end-to-end overviews, companies can create models, which AI tools can analyse to identify inefficiencies and predict problems. The relevant AI tools can be relatively cheap, and the returns can be significant. In warehouses, inventory control and organisation can be improved. By monitoring staff locations from warehouses to distribution, companies can make recommendations to minimise unnecessary travel time.

IoT integration enables broader intra-supply chain information flow. With a better picture of the activity of others, each part of the supply chain can operate with leaner error margins built-in and fewer misunderstandings and miscommunications. The broader information flow can be used to attract third parties. Retailers, which operate on tight logistical margins, demand ready, reliable stock information, as it reduces costs. Consumers, who lead busy lives and want instant gratification, can learn whether the product they want is in stock before heading to the shops.

IoT integration also helps reduce waste. Perishable management is typically an expensive area for companies. Using IoT to improve perishable management reduces the staff training required and reduces product waste, making companies more profitable and sustainable. Tagging on product packaging lets companies monitor their products after they are sent to retailers. Products like electric toothbrushes, vacuum cleaners, and baby rockers can relay data about use and wear to inform product development. Additionally, trackers and identifiers can be used on premium FMCGs like alcohol products to discourage theft and counterfeiting. Diageo uses Thinfilm’s tags for this.

How IoT can address the challenge of innovation and changing consumer preferences

As consumer preferences are ever-evolving, IoT can improve transparency between consumers and product manufacturers, with the payoff of improving trust and loyalty from informed consumers. Companies win consumer trust by attaching scannable tags to products that provide access to information that proves products meet consumers’ preferences.

Sceptical consumers will appreciate transparent information on provenance, supply chains, and nutritional values. In 2021, French software company Connecting Food created a platform for consumers to monitor packaged food journeys from field to store. Connecting Food’s packaged goods have QR codes that monitor a product’s entire journey.

Installing monitoring technology across value chains improves traceability and transparency. It also legitimises companies’ claims about provenance, farm-to-fork journey, and factory and packaging practices. Tracking the journeys of individual batches through production enables companies to offer specific details. Such technology also obviates any future need for surveys or tedious research, as the data is collected automatically. Sustainability-minded consumers will also like the waste reduction.

Additionally, IoT devices can be used to create personalised experiences for customers. IoT-integrated supply chains have the agility and flexibility to accommodate the demand for personalised and niche products. Many of these products will be health products for children, elderly people, and pets with specific nutritional requirements. Since these parties may struggle to remember to order or be able to order for themselves, many orders will be placed on automatic shopping lists, which ensures good customer retention.

On nicotine products, intuitive controls that manage nicotine levels can help new consumers customise their experience to their liking and allow brands to sell a single strength of tobacco, saving production costs.

GlobalData, the leading provider of industry intelligence, provided the underlying data, research, and analysis used to produce this article.

GlobalData’s Thematic Intelligence uses proprietary data, research, and analysis to provide a forward-looking perspective on the key themes that will shape the future of the world’s largest industries and the organisations within them.