Adequate procedures and cutting-edge magnetic separation and metal detection equipment are essential for control of metal contamination to protect food product, brands, equipment, and consumers.

With an increased focus in hygiene, operator safety, and lean manufacturing practices, the combination of ultrahigh-intensity magnet systems, highly sensitive metal detectors, and X-ray units, provide the food and beverage industry with the necessary tools to successfully control the physical hazard of metal.

Consequences of metal contamination

If not properly detected and removed, foreign metal fragments can have devastating consequences for the food processing companies involved.

- Contamination of final product

- Product recall

- Brand name damage

- Customer dissatisfaction

- Damage to expensive processing equipment

- Loss of production

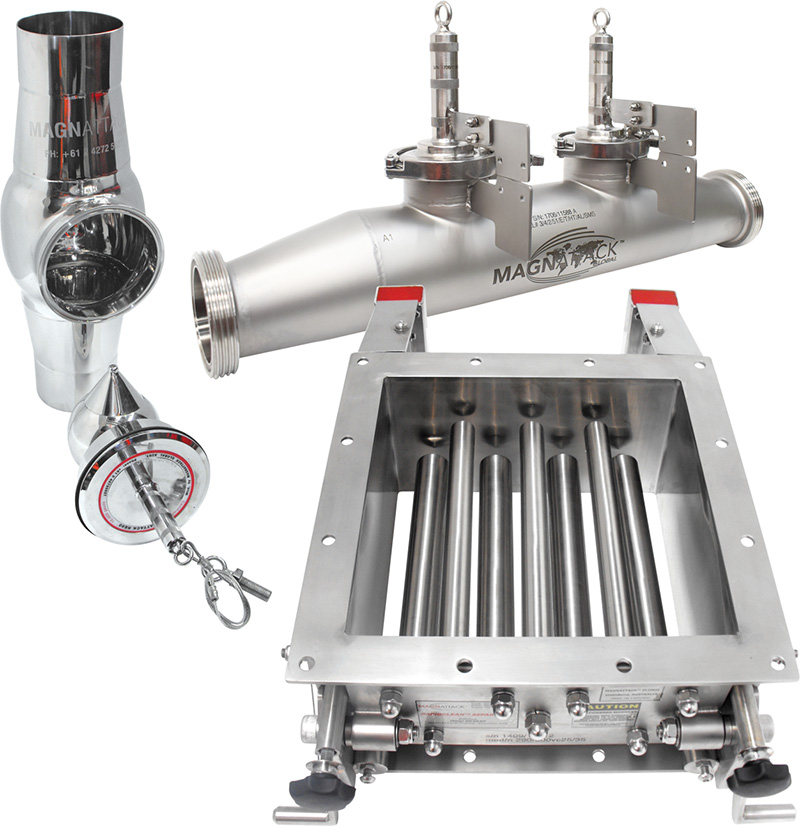

MagRam™ Automatic Self-Cleaning Separator

Advanced self-cleaning grate magnet designed for maximum magnetic separation and risk reduction in high-tonnage dry food products such as milling or meat rendering

Discover more

Rapidclean™ Hygienic Grate Magnet

For hygienic and efficient foreign metal fragment control in dry, free-flowing product lines such as sugar and flour

Discover more

Spherical Pneumatic Transfer Magnet

Aerodynamic and sanitary alternative to conventional Bullet Magnets in high-velocity transfer lines

Discover more

Sanitary Powder Transfer Magnet

USDA-Accepted alternative to the Spherical Magnet engineered especially for sensitive powders such as dairy and pharmaceuticals

Discover more

Dimple-Mag™ Extraction System

Designed to reduce product build-up and improve flow characteristics

Discover more

Liquid Pressure Pipeline Separator

Efficient magnetic separation in liquid lines such as chocolate and soups. A hygienic alternative to conventional Liquid Trap Magnets

Discover more

Emulsion & Slurry Pipeline Separator

Hydrodynamic metal fragment control in thick, viscous liquid and slurry lines such as in pet food, dairy, bakery, and meat emulsion applications

Discover more

Reducing your risks

Magnattack™ +11,000 gauss RE80™ Magnetic Separation Equipment is designed to achieve maximum foreign metal fragment control and separation efficiency for food processing companies. Each unit is specially engineered to extract and retain fine ferrous metal and magnetic fragments in critical applications, both prior to processing and at final packing of products.

Advantages of RE80™ Magnetic Separation Systems include;

- Reduced risk of contamination in final product and food recall

- Increased product security

- Maintain brand reputation and customer satisfaction

- Reduction in nuisance metal detector trips, therefore minimizing downtime required for investigation and location of contaminated product in bulk bags and bins

- Protection of expensive product machinery and reduced repair/maintenance costs

- Reduced risk of dust explosion (and consequent operator injury) caused by metal entering high-impact machinery

- Limit product waste and loss of production

Magnattack™ Global technicians work with the food processing companies worldwide to ensure their magnet systems are compliant with current industry standards and are providing maximum protection against foreign metal hazards.

Don’t risk metal contamination – contact us today!

USA: 630-994-3310

AU: (02) 4272 5527

INT’l: +61 2 4272 5527

Email: magnets@magnattackglobal.com