COMPANY INSIGHT

Rosenqvists Food Technologies AB

A reliable partner with years of experience in solutions for the food processing industry. Our focus is on processing lines for French fries and the snack food industry, (complete lines for potato chips and frying systems for pellets, prefabricated chips, peanuts, batch fried chips, tortilla, wet pasta, etc...)

To be able to supply a complete line, we are now offering our own developed and designed seasoning system as per below

Seasoning System

We are offering four different standard configurations of our seasoning system, from a basic system with manual control to the most sophisticated solution including mass flow of snack throughput and loss-in-weight of seasoning.

All four configurations can be designed and customized for any coating need. Slow speed, gentle action, and uniform product depth prevent product brea-age and ensures optimal coverage for consistency with all types of seasoning.

All seasoning systems are built on one skid for ease of installation and the design has been optimized for easy access and cleaning.

- Retractable scarf feeder

- Drum on swivel

- 90 degree turnable seasoning feeder

In-line or on-head seasoning # All options available.

For dry products # Different oil-spray systems are available.

Food trays and baking molds made from Genuine Vegetable parchment are biodegradable and home compostable.

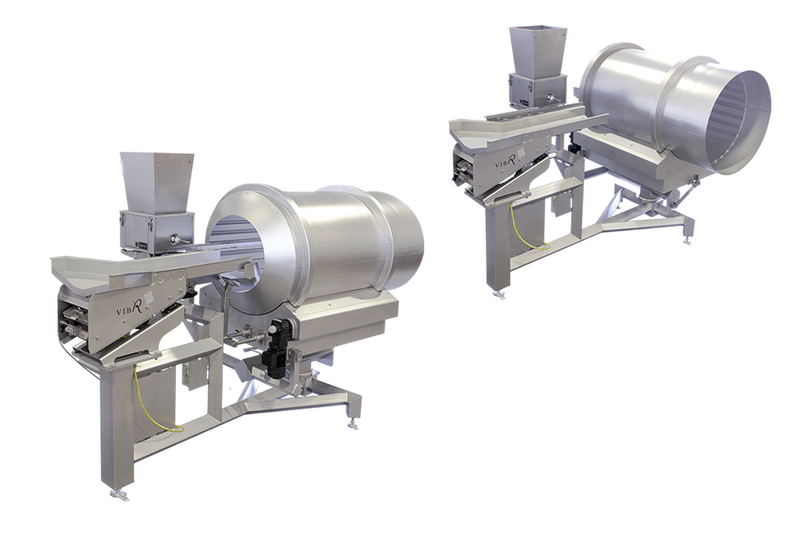

Seasoning Drum (SD)

The design guarantees that the product will be treated/tumbled gently ensuring that all the product in the drum will get the same coverage of seasoning. The result will be an even seasoned product with no wasted seasoning.

Scarf Feeder (VibRhF)

Powders, granules and fine products are controlled and handled easily. Designed to convey, dispense, and spread light and fine products accurately; they make an ideal sprinkling and coating solution. With the capability to handle a broad range of products, including high fat powders, they provide excellent seasoning coverage and are easy to clean and maintain.

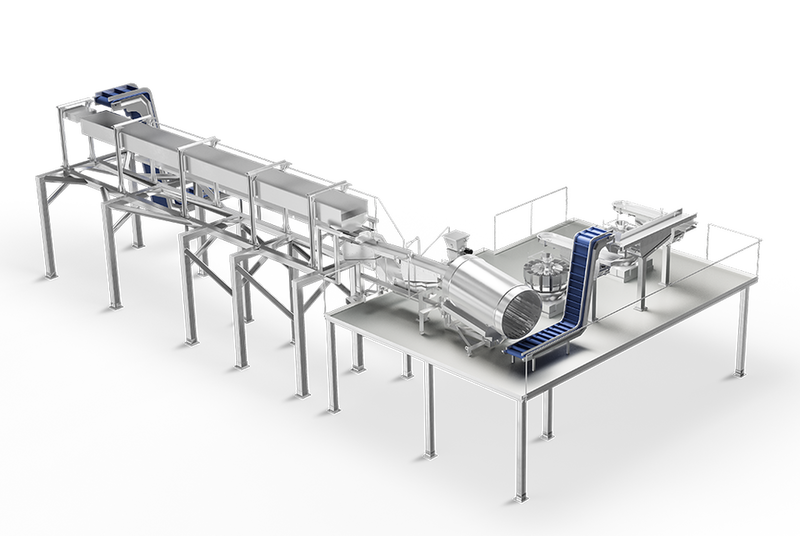

Seasoning and Distribution

Full system provider. We combine all our products to build custom made systems according to your requirements. All systems supplied are operated from a HMI system developed by Rosenqvists based on our vast know-how and experience. No matter the size of your project we can help you integrate it to your needs.

From a single unit to a complete packing hall with complex seasoning handling requirements, Rosenqvists can design and supply your complete seasoning and distribution system.

Vibratory Conveyor (VibReM)

The eM range of conveyors use electromagnetic drives resulting in highly reliable units that virtually eliminate maintenance and downtime. The tailor made controller allows variable product speeds enabling regulation of product flow rates. Suiting a broad range of applications and offering gentle product handling with minimal maintenance, the unit will add value to your processing line. Perfect for modular distribution systems with proportional endgates to feed on-head-seasoning all operated from a HMI systems developed by Rosenqvists.

Horizontal Motion Conveyor (VibRhM)

This conveyor gently handles your most delicate products. With the possibility to have long pan lengths, up to 30 meters, combined with different gate and lane configurations gives a cost effective option compared to a modular distribution system. The possibility to reverse product direction and the ability to place the drive at either end or even below the conveyor make the conveyor suitable for most layouts. Its self-cleaning pan and its ability to replace several conveyors, reducing transfer points, are two important factors when considering a new conveyor for your product. The VibRHM is superb as in-line-storage with capacities up to 5m³ of snack.

Belt/Elevators

To be able to make your distribution system complete we also supply flighted Z-elevators for large elevation changes. In addition we supply a range of belt configurations including normal transport belts and weighing belts. We only use food grade belts with the correct flight design to suit your application and capacity. The steelwork is always manufactured in stainless steel. We work with both modular and flat belts and can include many options including CIP and catch pans.

If desired we can also supply bucket elevators in various sizes and configurations including with multiple discharge points.

Contact us for more detailed information.

Contact Information

Rosenqvists Food Technologies

Väverigatan 2

SE 291 54 Kristianstad

Sweden

Tel: +46 44 590 41 40