COMPANY INSIGHT

Sponsored by Verder

Verder Hygienic Pump Solutions: The perfect pump for the perfect taste

Verder Liquids manufactures a wide range of hygienic pump solutions, ranging from Lobe and Twin-screw pumps to Centrifugal pumps for pumping all sorts of beverages. Because of their certified designs, these pumps have the highest cleanability ensuring the best possible (uncontaminated) taste for your beverage.

Most of us don’t think twice about reaching for a thirst-quenching glass of beer or milk. But when producing these beverages, one has to take the utmost care to make sure the liquids are not contaminated, have the perfect taste and also keep their shelf-life.

One of the most critical parts of the beverage production process, is the pumping of liquids, additives and flavours creating the end product. In order to master these tasks, Verder manufactures a complete range of hygienic pumps in Europe and Asia. No matter if you are pumping milk to a pasteurizer with a centrifugal pump, dosing sugar water into your beer with a smart peristaltic pump, lye and acid in a CIP application with a double-diaphragm pump, Verder has the best pump for your application!

As a true expert in the field of hygienic pumping, our pumps can be found in large multinational corporations, but also in local craft breweries around the corner. Knowing your process and giving the best possible advice based on years of experience and our broad portfolio, positions us to be the preferred pumping partner for the beverage industry.

Some of the main things you need to take into consideration when selecting the right pump for your hygienic process are:

- Materials compatibility

- Cleanability

- Self-draining

- Minimal dead zones

- Validated cleaning and sanitizing protocols

- Surface polishing

Verder offers, amongst others, the following hygienic pumps:

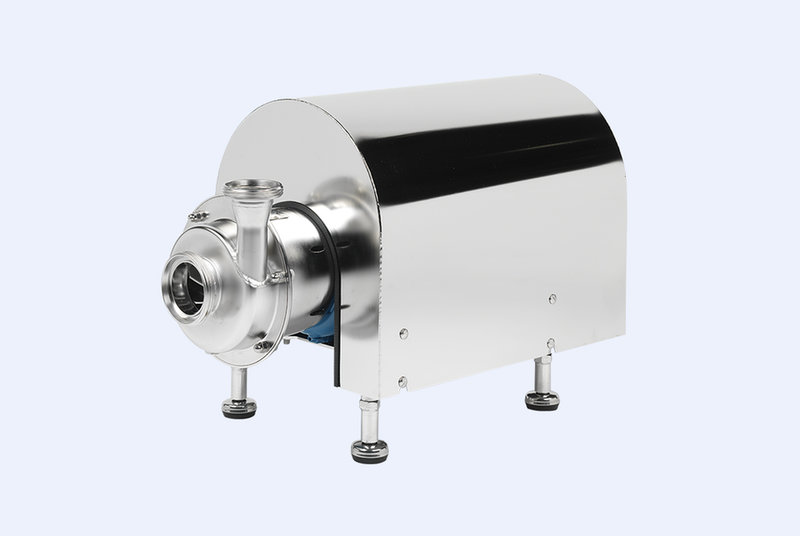

Centrifugal pumps:

The electro-polished Packo hygienic stainless steel pumps meet the high demands of EHEDG and 3A certification. For this reason, these low viscosity, high capacity pumps are used in almost all demanding applications such as dairy, breweries, distilleries and other beverage production.

Lobe pumps:

JEC Lobe pumps are designed especially for the transfer of fluids from low to high viscosity range. These pumps guarantee an almost shear free transfer of all fluids.

Twin-screw pumps:

All advantages of rotary lobe pumps and centrifugal pumps are combined in the JEC twin-screw series. This two-in-one operation pump series is excellent for pumping not only high-viscous liquids and pastes but also the thin-liquid cleaning fluids that are used for CIP cleaning. The pumps provide a pulsation free flow for gentle operation.

Air-operated diaphragm pumps:

The Verderair HI-CLEAN pumps are designed for operation in hygienic, dairy, cosmetic and food processing applications, such as fruit syrups and concentrates, sauces and cosmetic creams. The series consists of hygienic and food grade air operated double diaphragm (AODD) and piston pumps.

Peristaltic pumps:

Verderflex hygienic peristaltic pumps are used for precision dosing and gentle transfer of liquids. Both the Verderflex Rollit and Vantage 5000 can be used with FDA and 3A graded tubing that can also be used as throw-away units ensuring complete cleanliness.

Certifications:

EC 1935/2004

FDA

3A

EHEDG

ATEX

In conclusion, no matter what you are pumping, Verder has the right pump for your hygienic application.

About Verder:

THE VERDER GROUP

The Verder group is a family owned business formed over 55 years ago in the Netherlands; the group consists of a worldwide network of production and distribution companies. Group companies are involved in the development and distribution of industrial pumps, pumping systems, high-tech equipment for quality control, research and development into solid material (solids sample preparation and analytical technologies). The Verder Group employs over 1600 people and has an annual turnover in excess of 380 million Euros.